Mimaki Printer System UJV300DTF-75

The Mimaki UJV300DTF‑75 is a dedicated UV‑DTF (direct‑to‑film) roll printer engineered for high-value, made-to-order decoration. It prints on specialized transfer film that can then be applied to curved, irregular, or difficult surfaces—offering flexibility for industrial, promotional, and custom print applications.

Available Offer

Share :

Specifications

Printheads: 2× on-demand piezo

Max Resolution: 1,200 dpi

Ink Sets: ELS-170 CMYK (flexible UV) + ELH-100 White/Clear (hard UV)

Channel Configuration: 4C + 4SP (CMYK + WW Cl Cl)

Ink Size: 1 L bottles; White circulation: Yes

Max Print Width: 25 in (640 mm)

Media Width / Capacity: up to 25.6 in (650 mm); ≤ 9.84 in (250 mm) roll Ø; ≤ 99 lb (45 kg) roll weight

Print Speeds:

Draft (300×600, 8 pass): 34.4 ft²/h (3.2 m²/h)

High Speed (300×900, 12 pass): 26.9 ft²/h (2.5 m²/h)

Production (600×600, 16 pass): 22.6 ft²/h (2.1 m²/h)

Quality (600×1200, 32 pass): 10.76 ft²/h (1.0 m²/h)

High Quality (1200×1200, 32 pass): 6.5 ft²/h (0.6 m²/h)

Interface: Ethernet 1000BASE-T; USB 2.0 Hi-Speed

Power: AC100–120 / 200–240 V ±10%, 50/60 Hz; up to 1,440 W (100 V) / 1,920 W (200 V)

Safety / Compliance: VCCI/FCC Class A, IEC62368-1 ETL, CE, CB, ENERGY STAR, RCM, KC

Highlights

First Mimaki printer dedicated to UV‑DTF transfers

Automated in-line lamination for A/B film workflow

No weeding required — ready-to-apply transfers

Transfers adhere to curved or uneven surfaces

One-touch media loading with specialized film rollers

Circulating White and Clear channels for opacity and gloss effects

Applications

Labels and decals

Product personalization (drinkware, cases, promotional items)

Transfers to curved or irregular surfaces

Any situation where direct printing is impractical

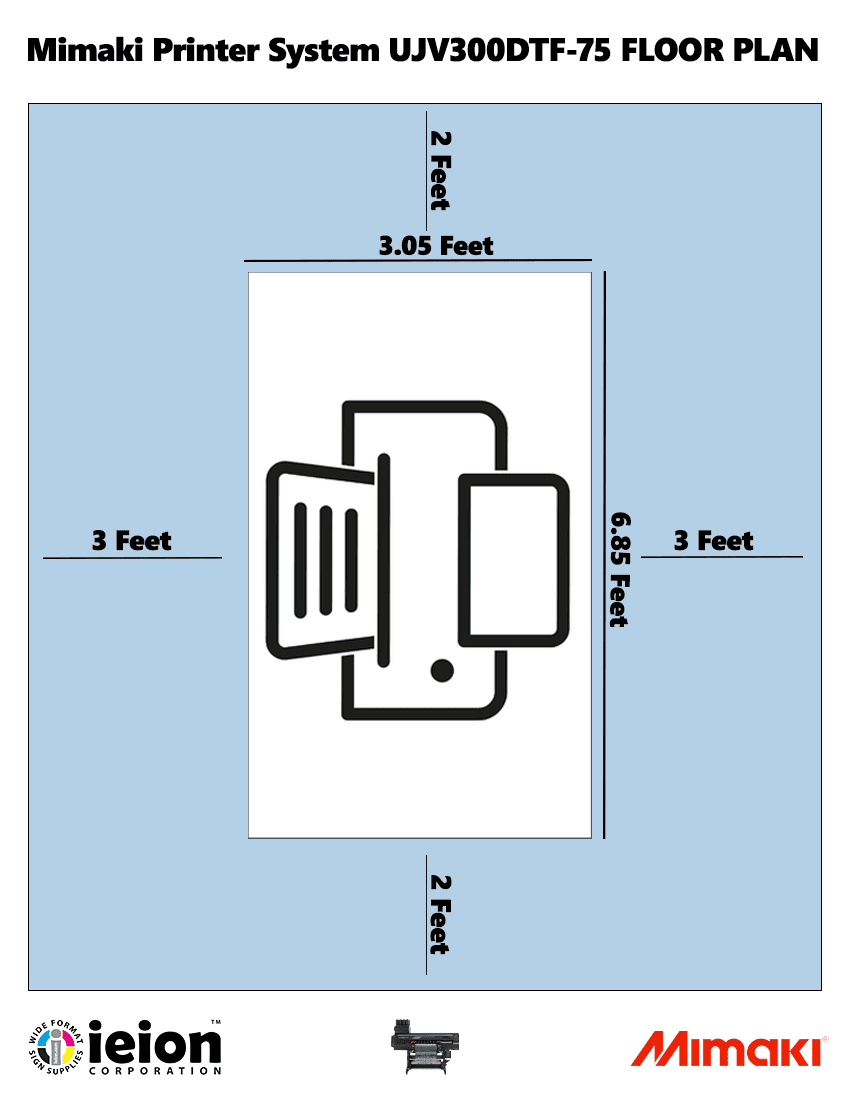

Printer Weight and Size

Weight: 367 lb (180 kg)

Dimensions (W × D × H): 82 × 37 × 58 in (2,090 × 930 × 1,475 mm) → ~6.85 ft × 3.05 ft × 4.84 ft

Recommended clearance: ~8 ft width × ~4 ft depth

Shipping Information

Packaged weight: 367 lb (180 kg)

Packaged dimensions: ~7 ft × 3 ft × 5 ft

Recommended Inks

Floor Plan

Printers Specifications

- Printheads:Epson i3200

- Base System:Roll to Roll

- Main feature:Print

- Printing Size:24 in

- Rip Software:Rasterlink

- Computer Included:No

- Max Media Thickness:1mm

- Max Media Weight:110 lbs

- Ink System:Fix with Chips

- Power Supply:110v/220v

- Power Consumption:5kVA

- Interface:Ethernet

- Vacuum Table Zones:1

- Adjustable Layout Pins:No

- Waveform control:Yes

- Variable Dot Technology:Yes

- Fine Difussion:Yes

- Ink Circulation:Yes

- Nozzle Recovery System:Yes

- Printer Ink Base:UV DTF